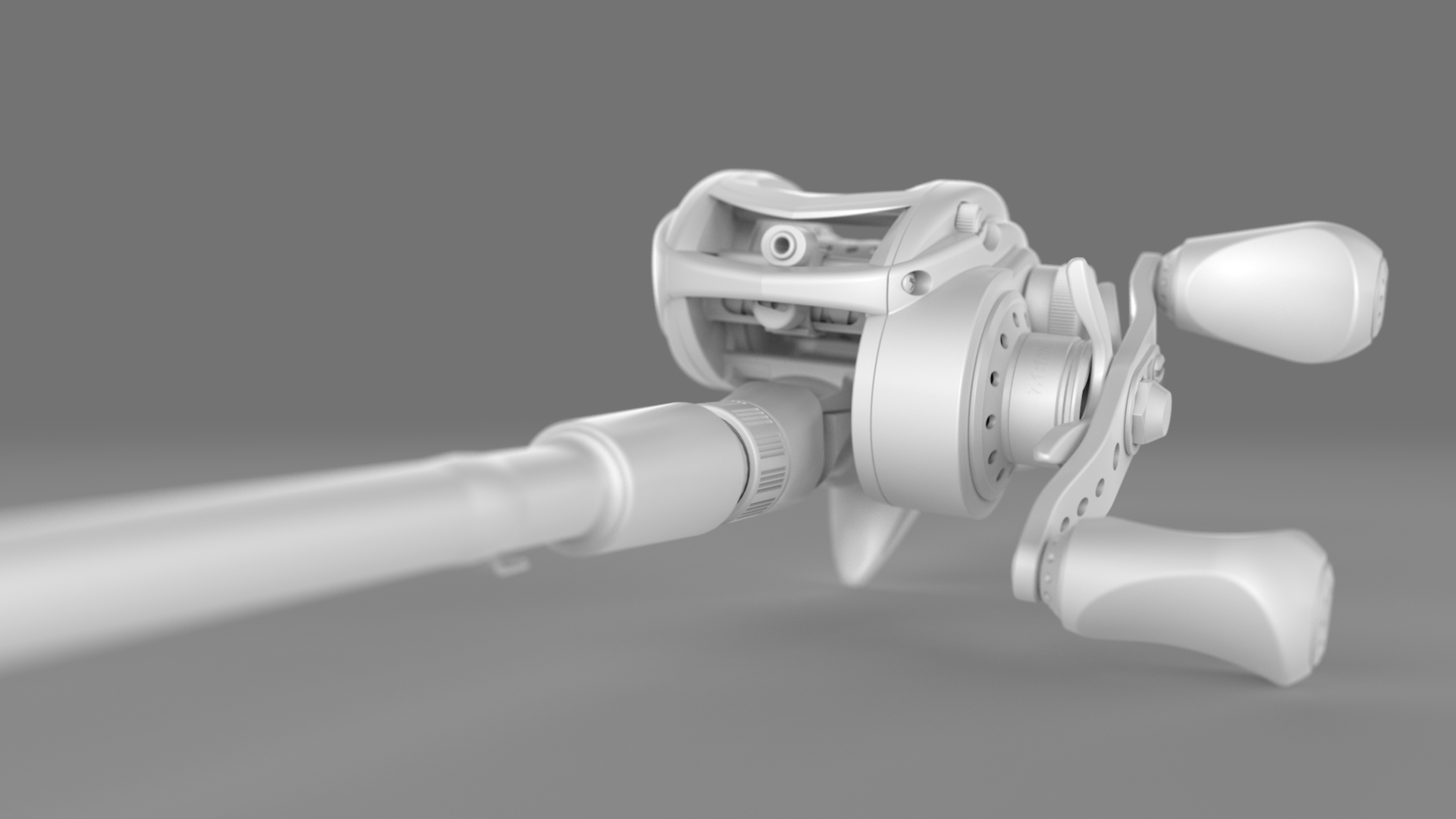

Rod and Reel – Reverse Engineering

CASE STUDY

Fishing has always been a hobby of mines. So, when I had the chance to create a personal project to better understand plastic part design using SolidWorks I chose my fishing rod and reel as an example to reverse engineer.

The project progressed through the following stages. 3D Laser Scanning on the rod handle. Sketch picture to CAD of the reel frame. Some hand measurement of the rod and reel. CAD draft analysis of plastic rod grip. Lastly the final 3D modeling of the rod and reel combo to be rendered in KeyShot.

CHALLENGE

The aim of this project was to reproduce an injection molded plastic part using advance surface modeling techniques in SolidWorks while maintaining part accuracy.

OUTCOME

A professional 3D CAD file that can be used for prototyping, quoting, manufacturing, or product renderings for marketing purposes.

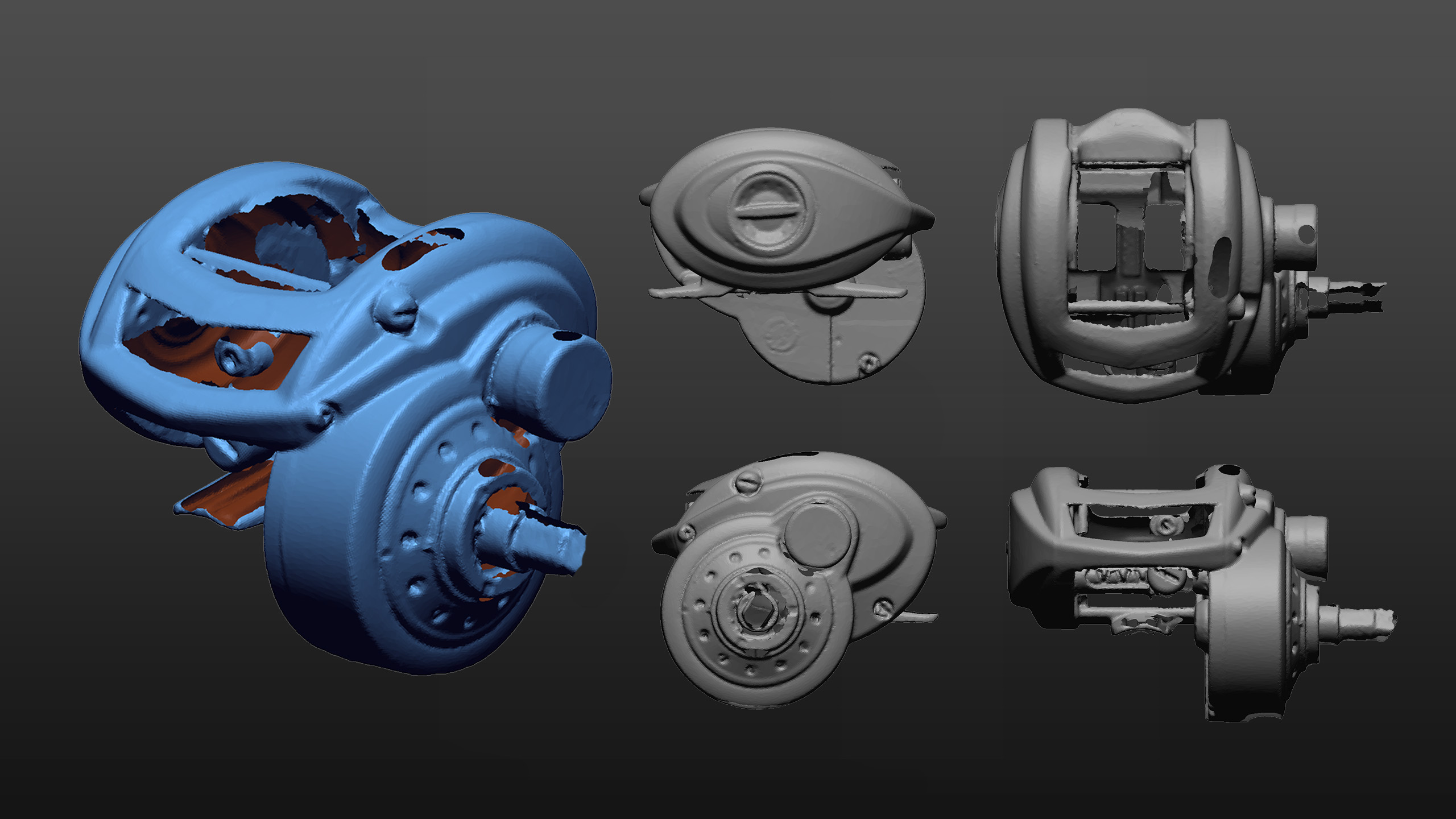

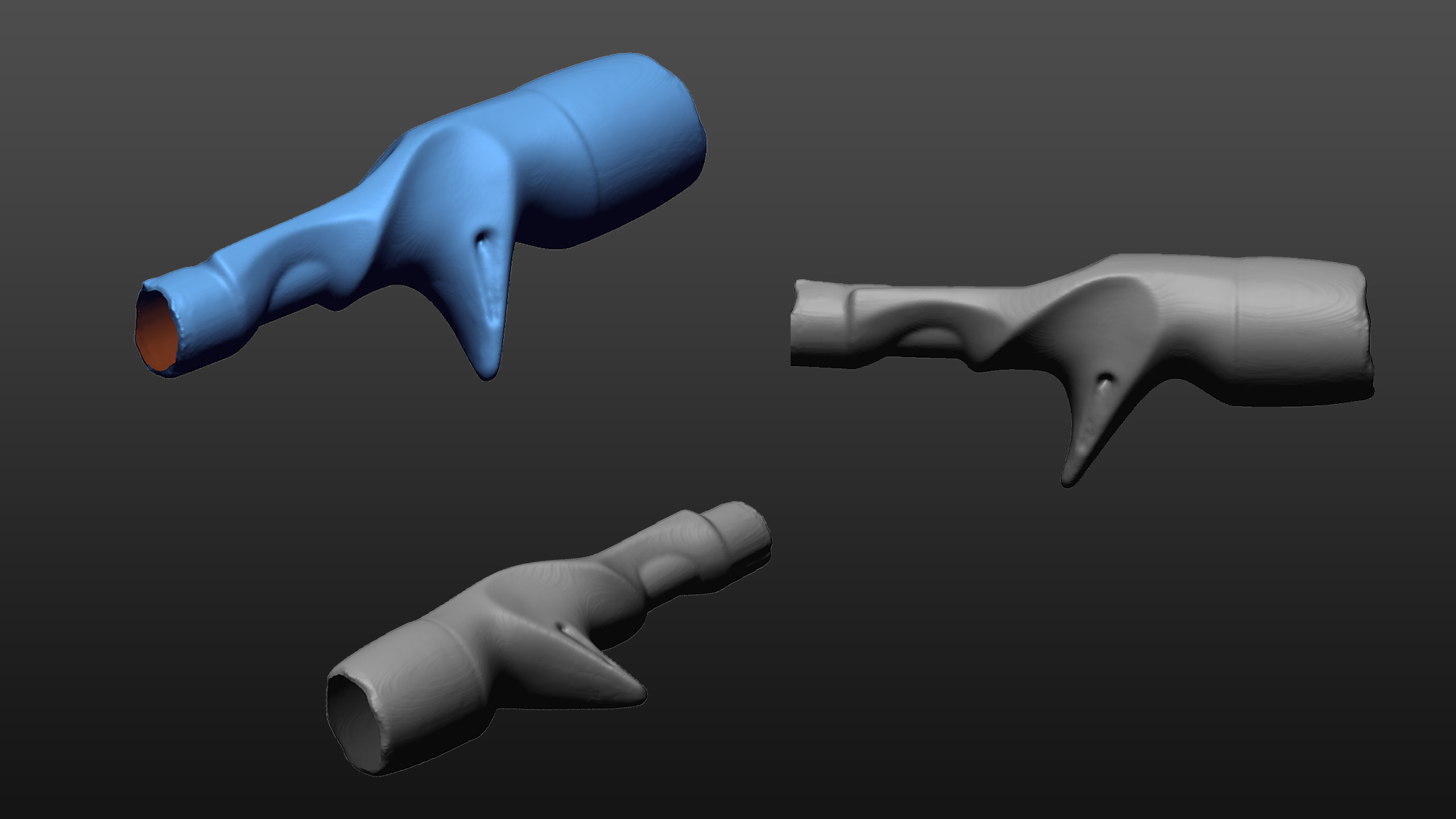

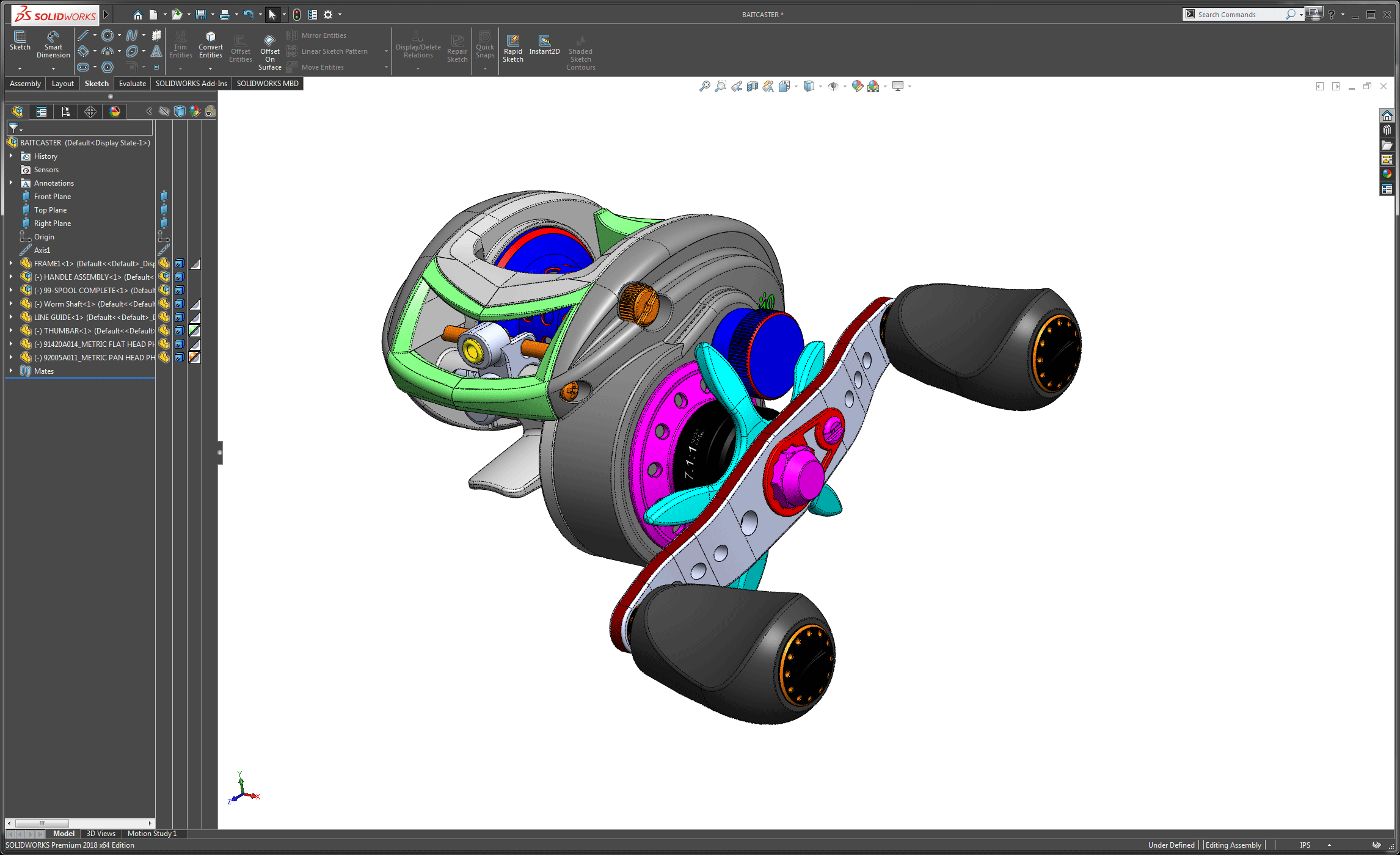

3D Scanning

In order to successfully reverse engineer the rod and reel, 3D laser scanning was the preferred method to capture the areas of complex geometry as it was either difficult to measure or model by hand accurately. In this case it was the grip handle on the rod and the frame on the reel.

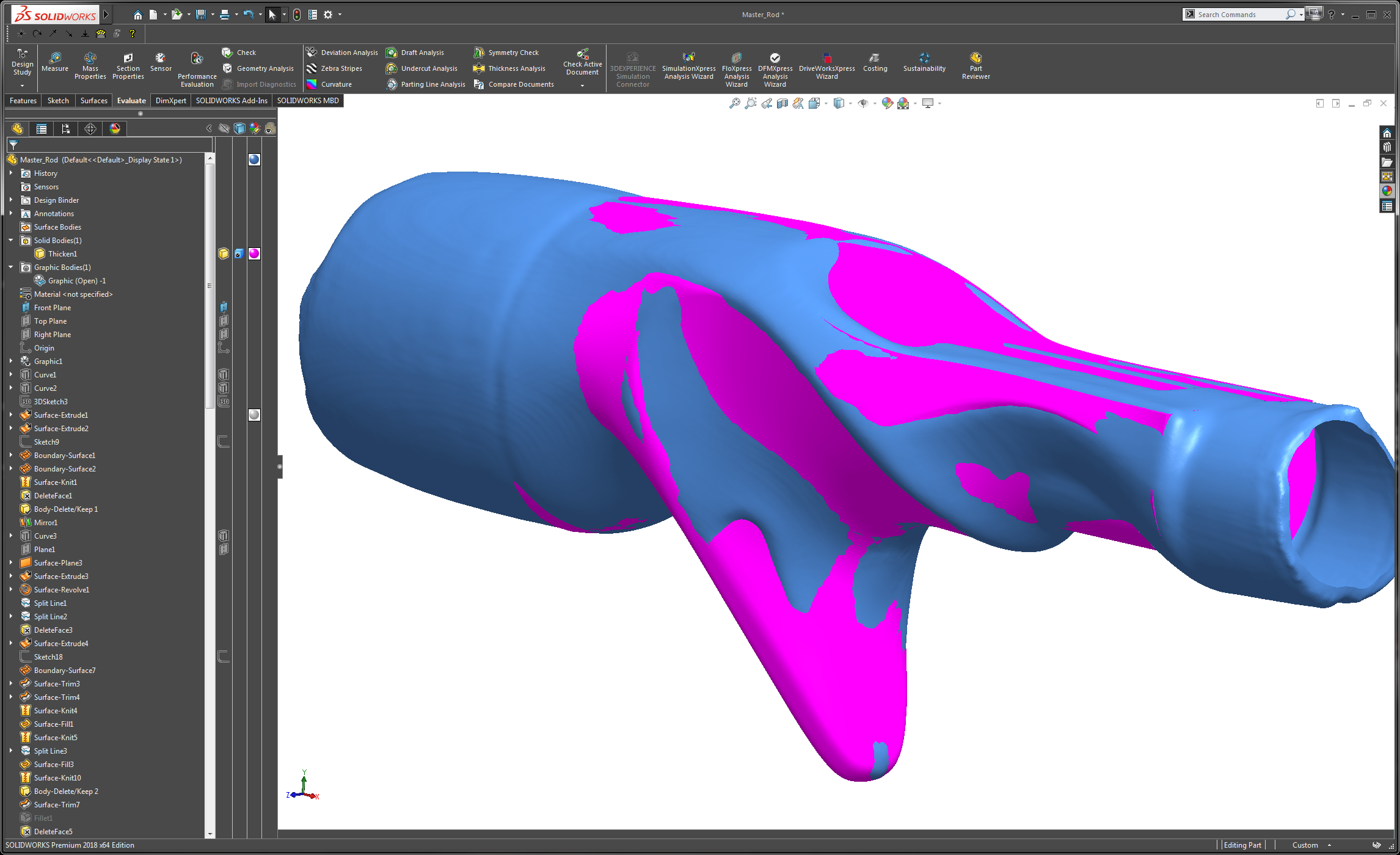

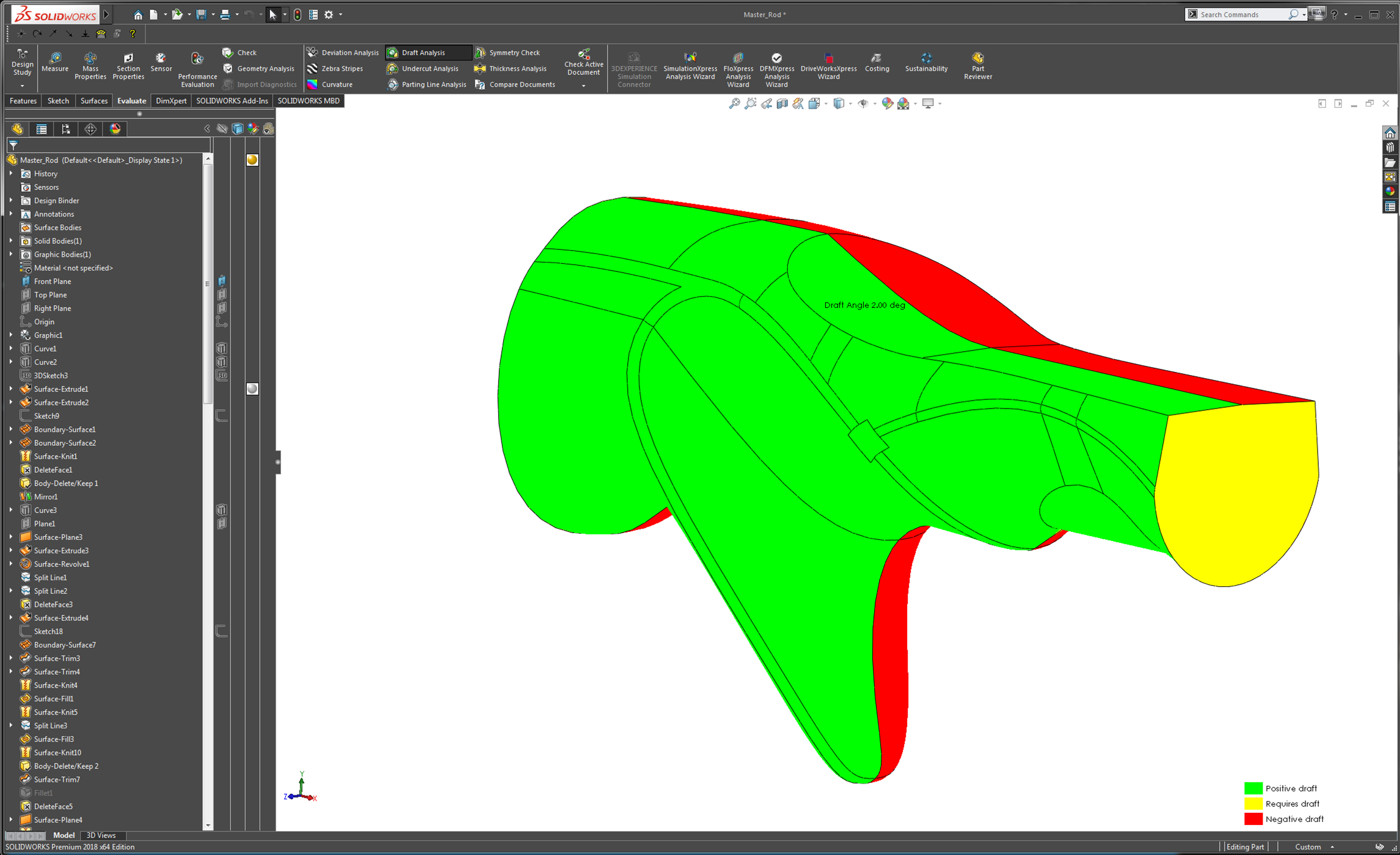

CAD Development

The scan data is then imported into SolidWorks to start the reverse engineering process using advance surface modeling to construct each face. After the model is complete draft analysis was performed to make sure that a clean parting line for plastic mold injection could be established.

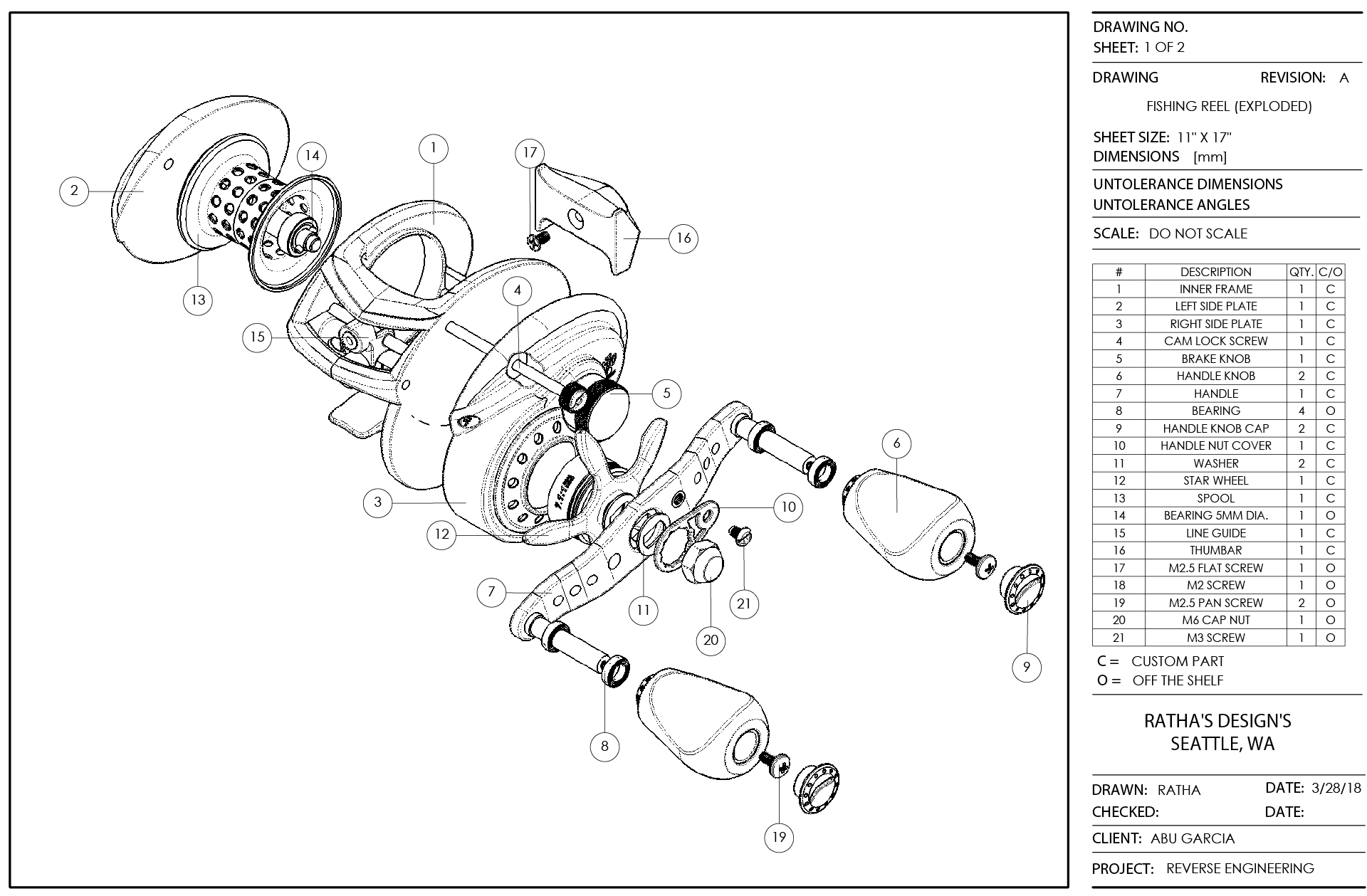

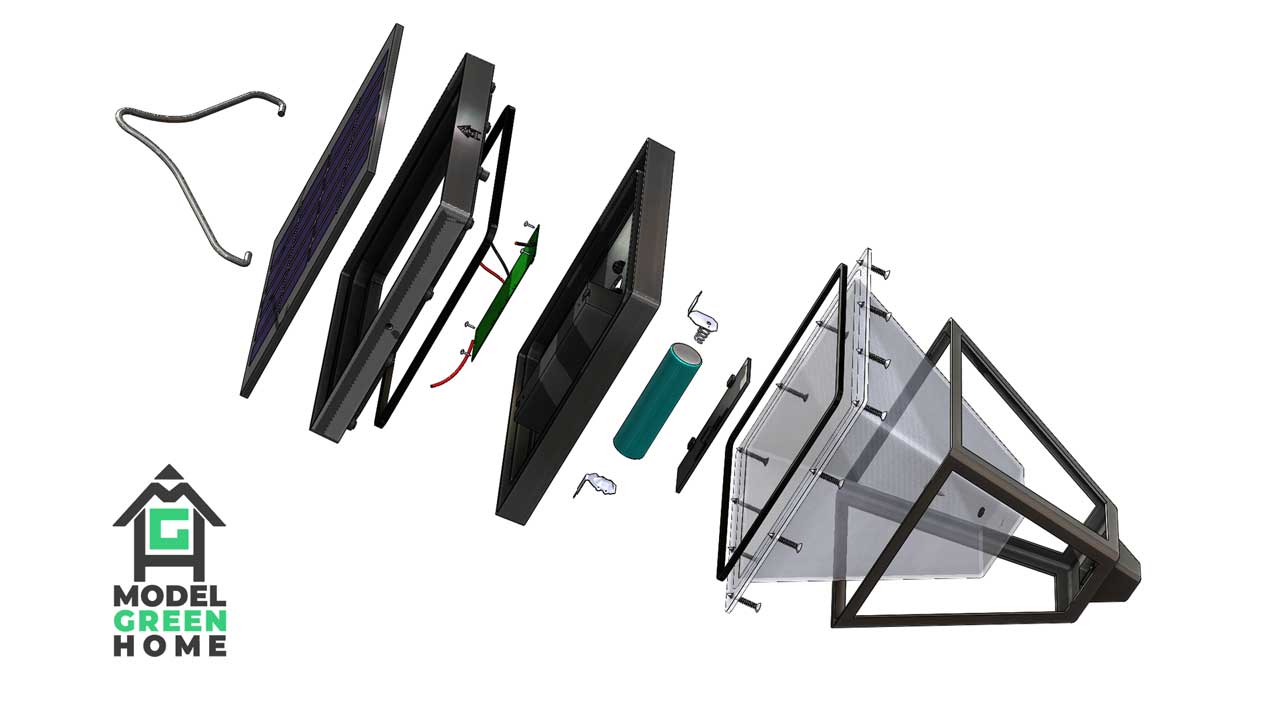

Bill of Materials (BOM)

Exploded assembly drawings and detailed Bill of Materials (BOM) were used throughout the prototyping process as a way to organize parts that were custom built or off the shelf components.

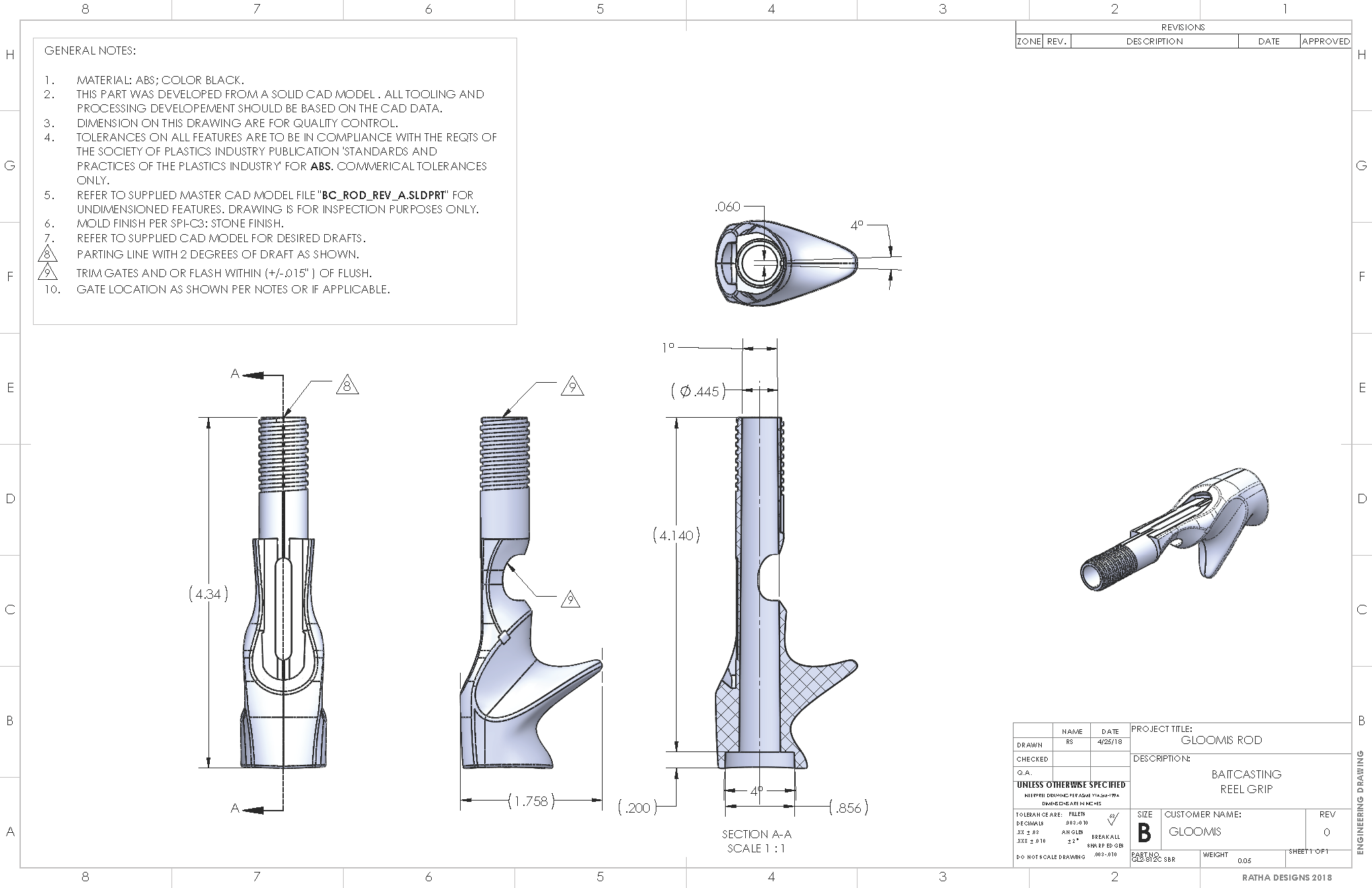

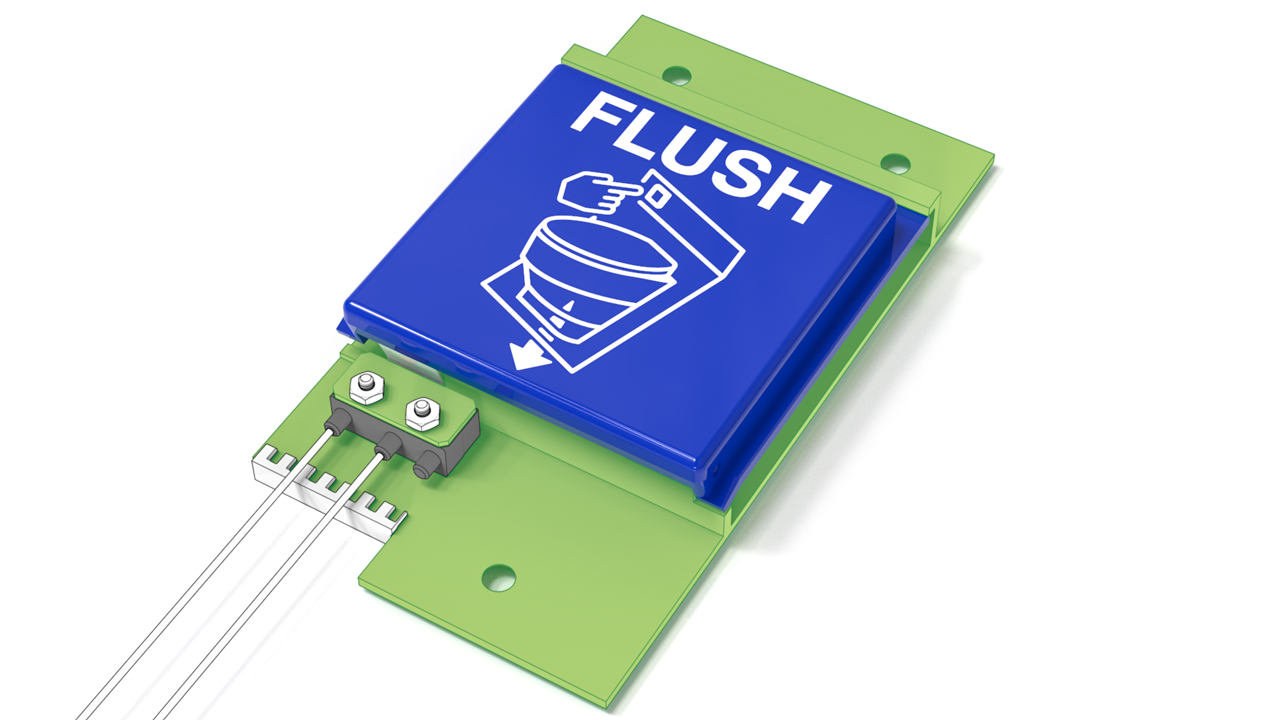

Production Drawing

Production Drawings are necessary to communicate “Critical To Function” Dimensions and other information for First Article Quality Assurance.

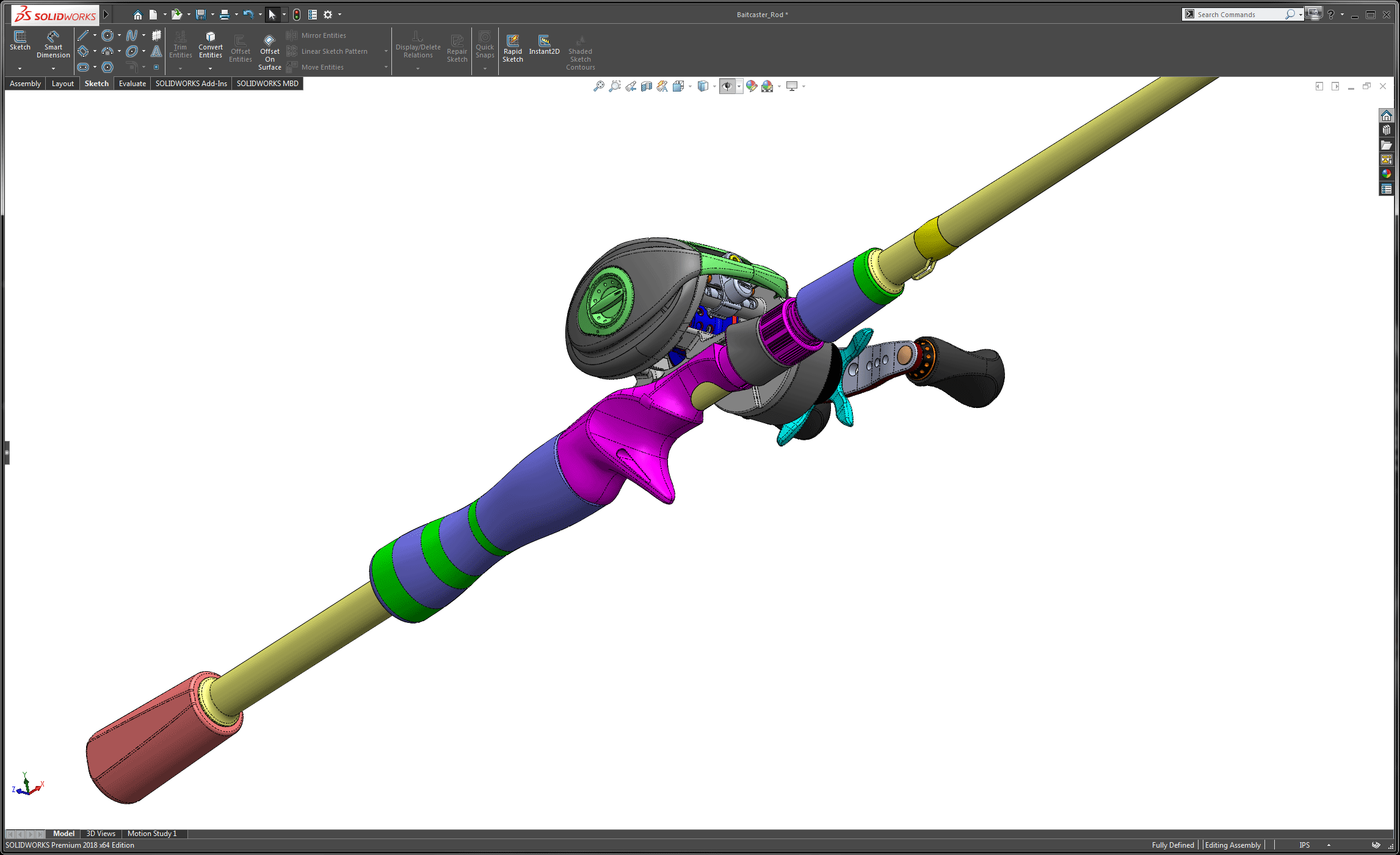

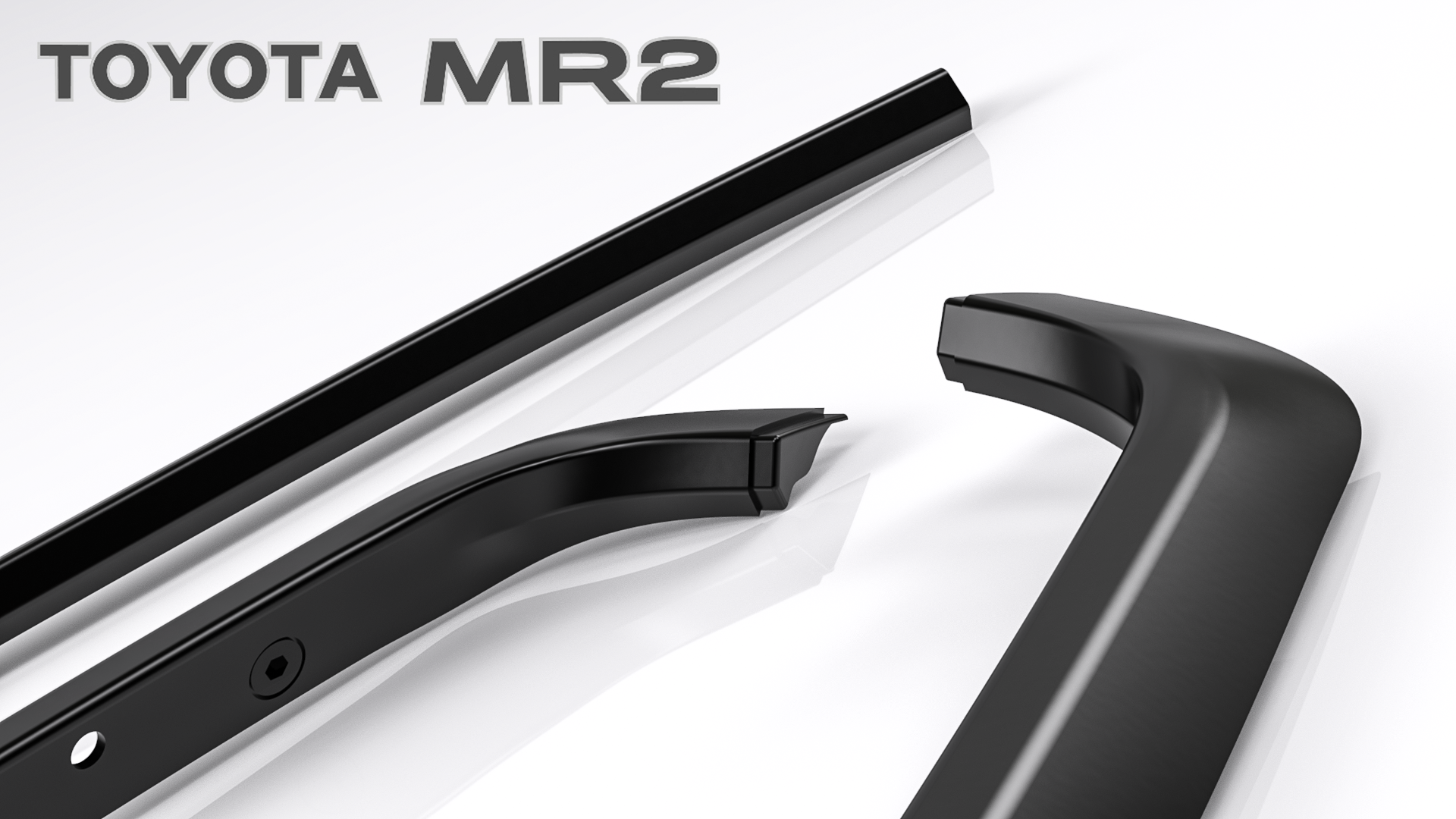

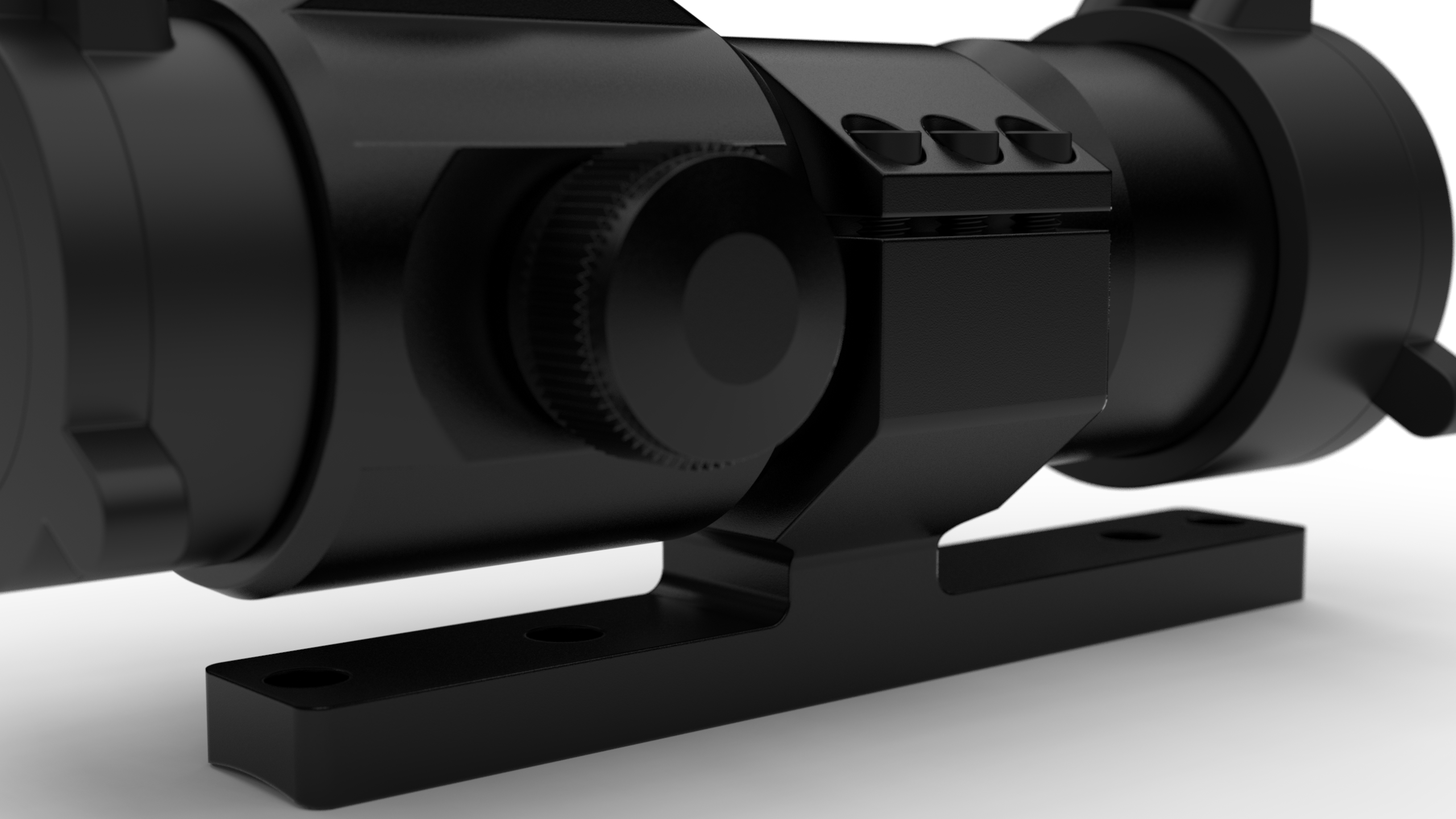

Product Renderings

Product visuals help the product development process in myriad ways. They help “sell” ideas or concepts long before they exist in physical form and can shorten the time to market way before the product is actually release.

Ready to get started?