Zi Outdoors – Ruger 10/22 Scope Mount

CASE STUDY

Greg reach out to me to help him engineer and design a custom scope mount that involve taking the best features of two unique parts to make one hybrid version. I ask him why not just go to a 3D scanning company and have them do the reverse engineering work. He explained that he would of like to but unfortunately they don’t do CAD alterations to the existing scan data. They only can only provide a one off CAD model base of what they scanned. And that’s where I come in to help fill in the gaps with design changes to make it your own.

The Problem

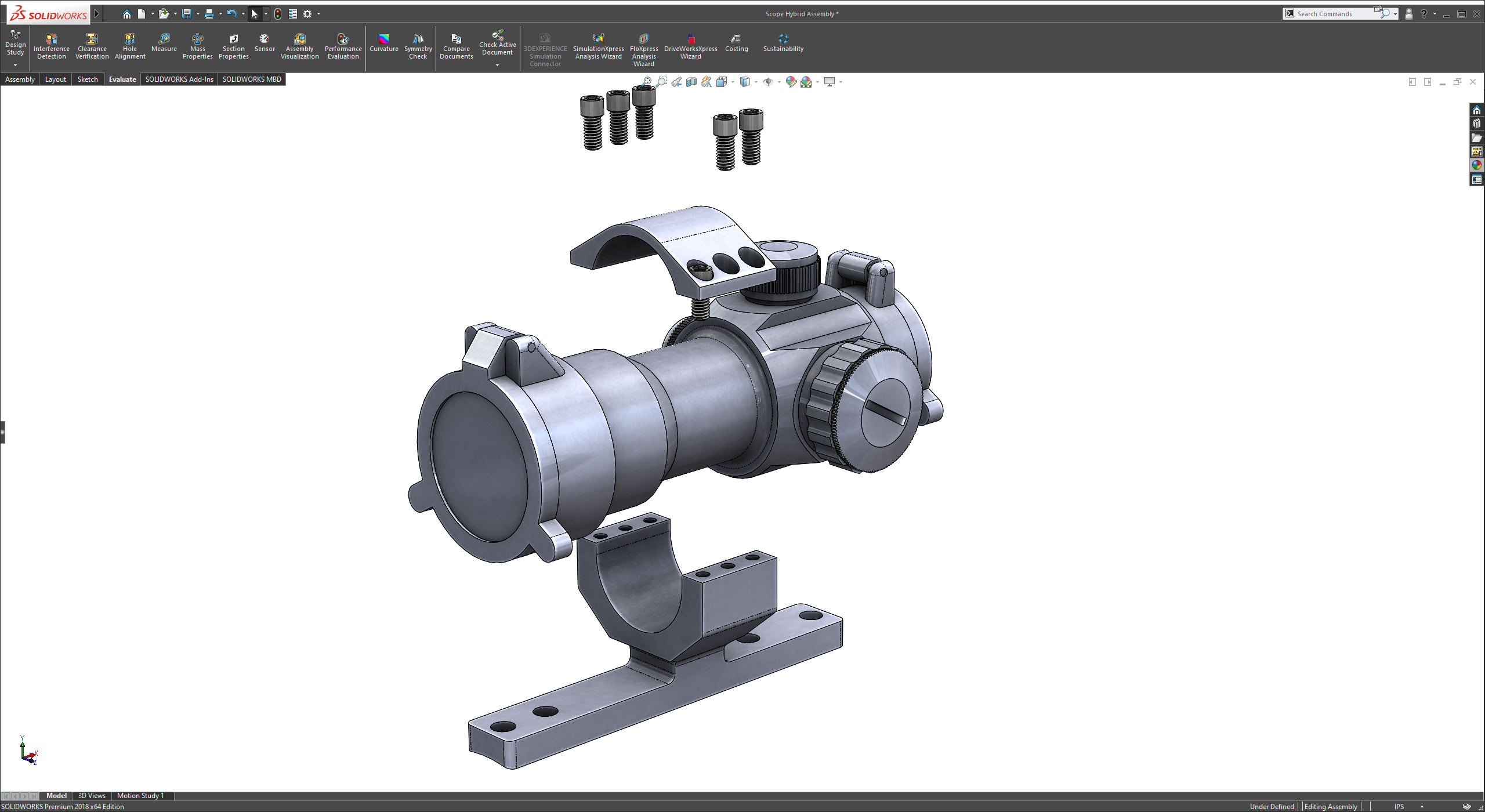

After receiving many customer feedback and reviews, Greg set out to find a simple solution to install the Phase Line G4 Scope on a Ruger 10/22 since no bolt-on scope kits were available. The approach was to reuse the upper mount that came with the Phase Line G4 kit and take design features from the lower scope mount kit of the Ruger 10/22 to form a hybrid version. This meant we would only have to make the lower mount while saving BOM cost on the upper mount.

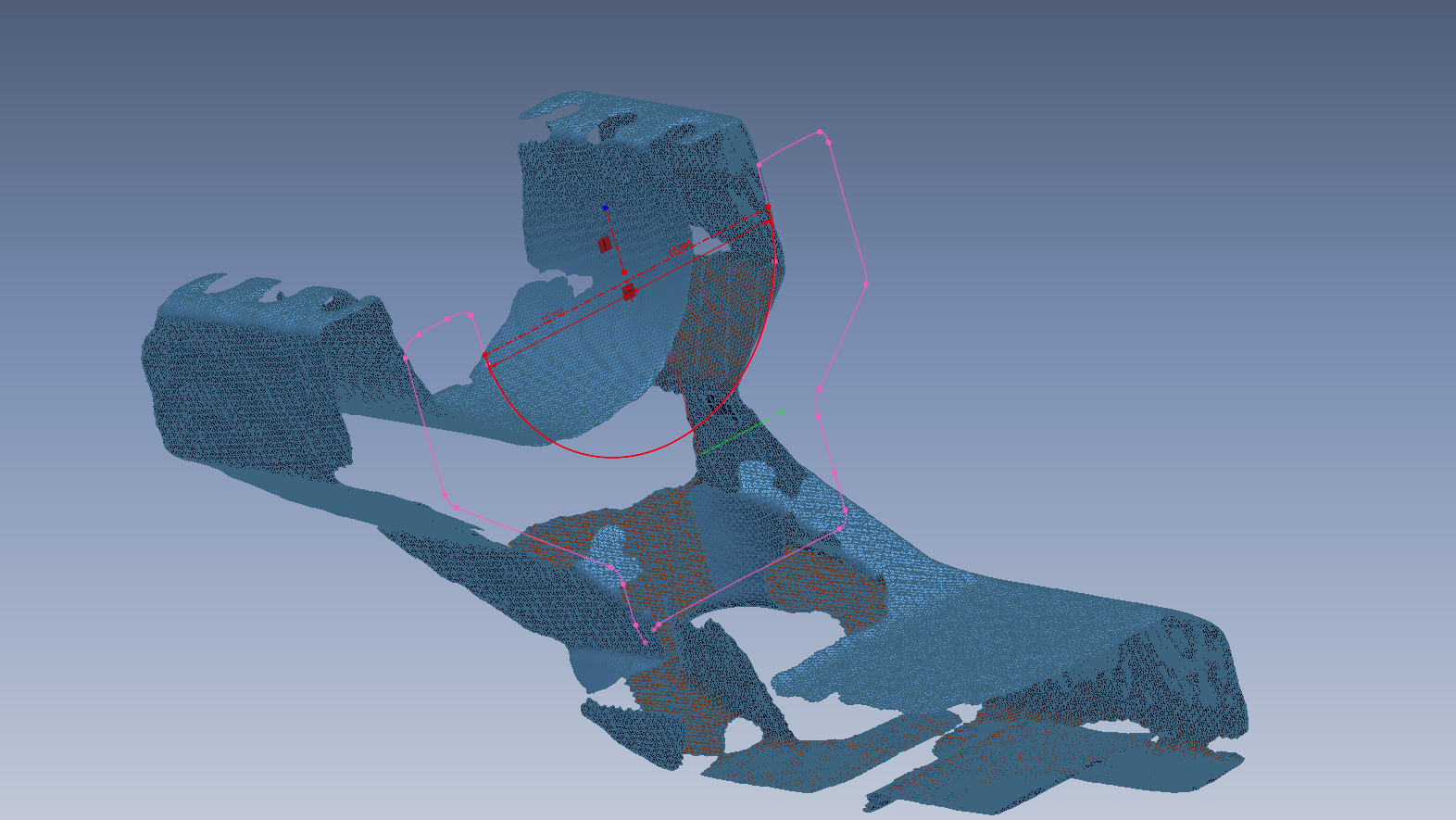

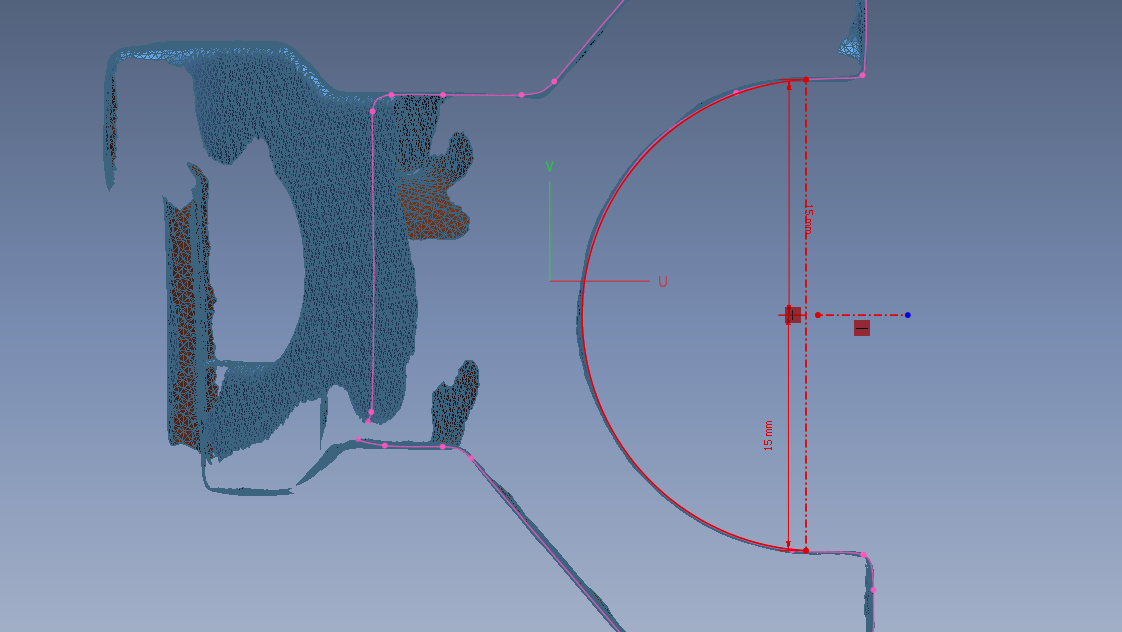

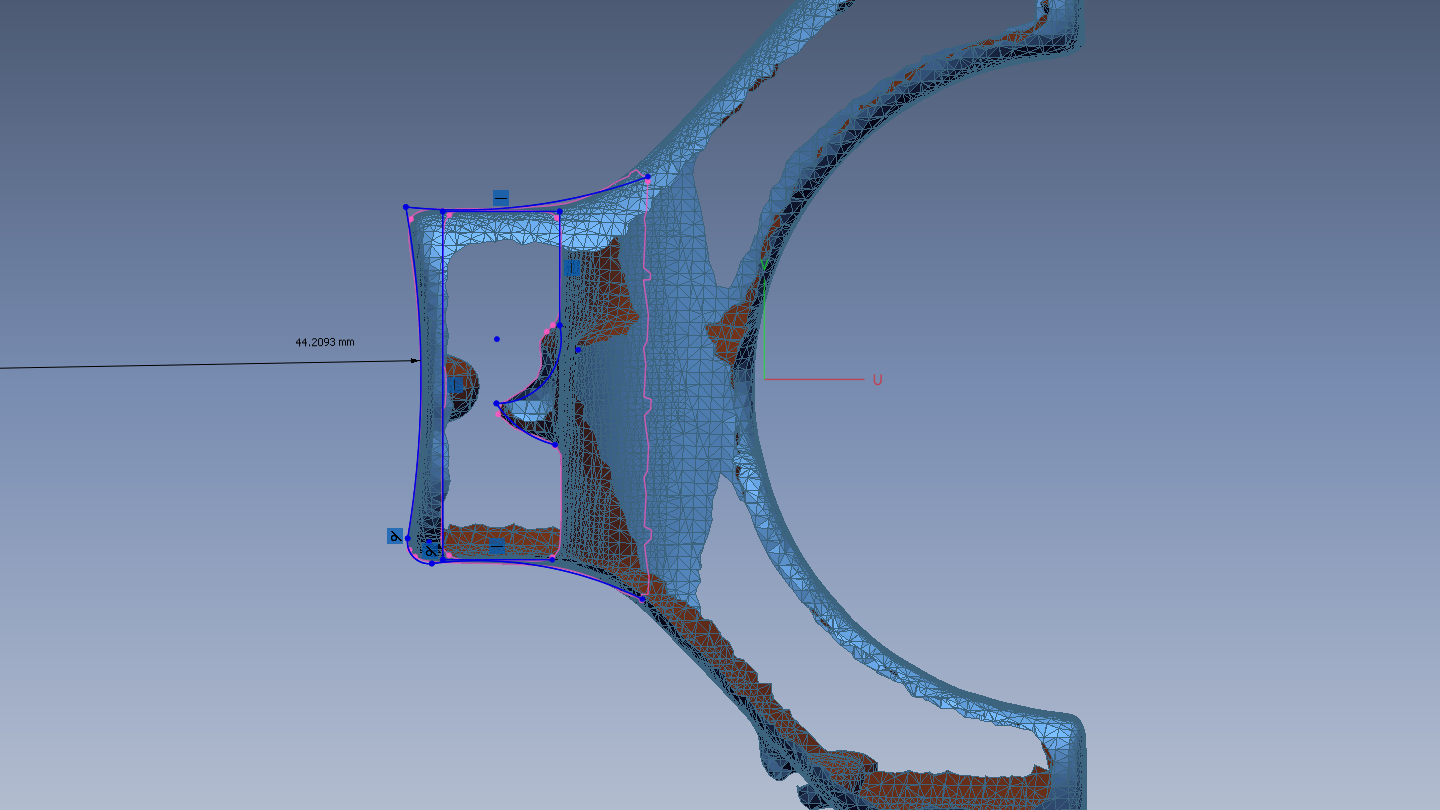

3D Scanning & Reverse Engineering

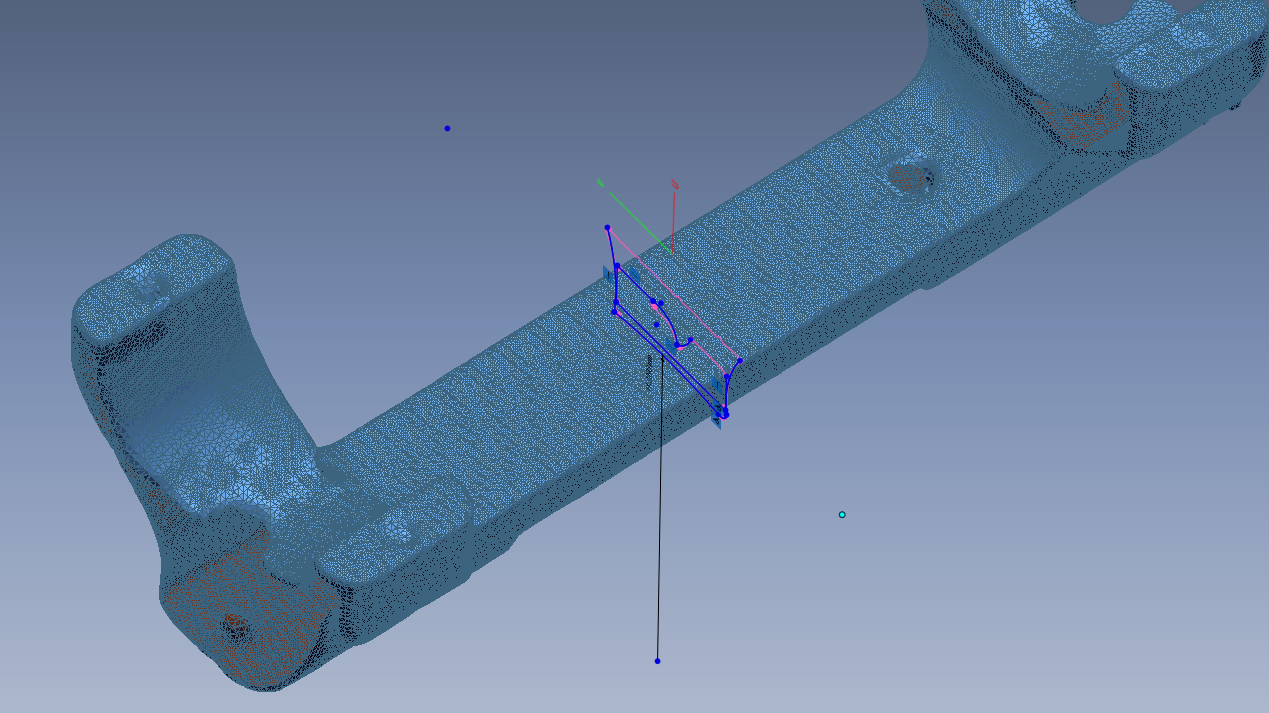

To marry the two off-the-shelf parts accurately we used a 3D scanner to capture the critical areas or each part. We weren’t overly concern with scanning everything but focused on the diameter of where the scope would live along with the hole relations and radius of the lower mount that match up on the Ruger 10/22. Other simple features were measured via digital calipers, pin gauges, and thread gauges.

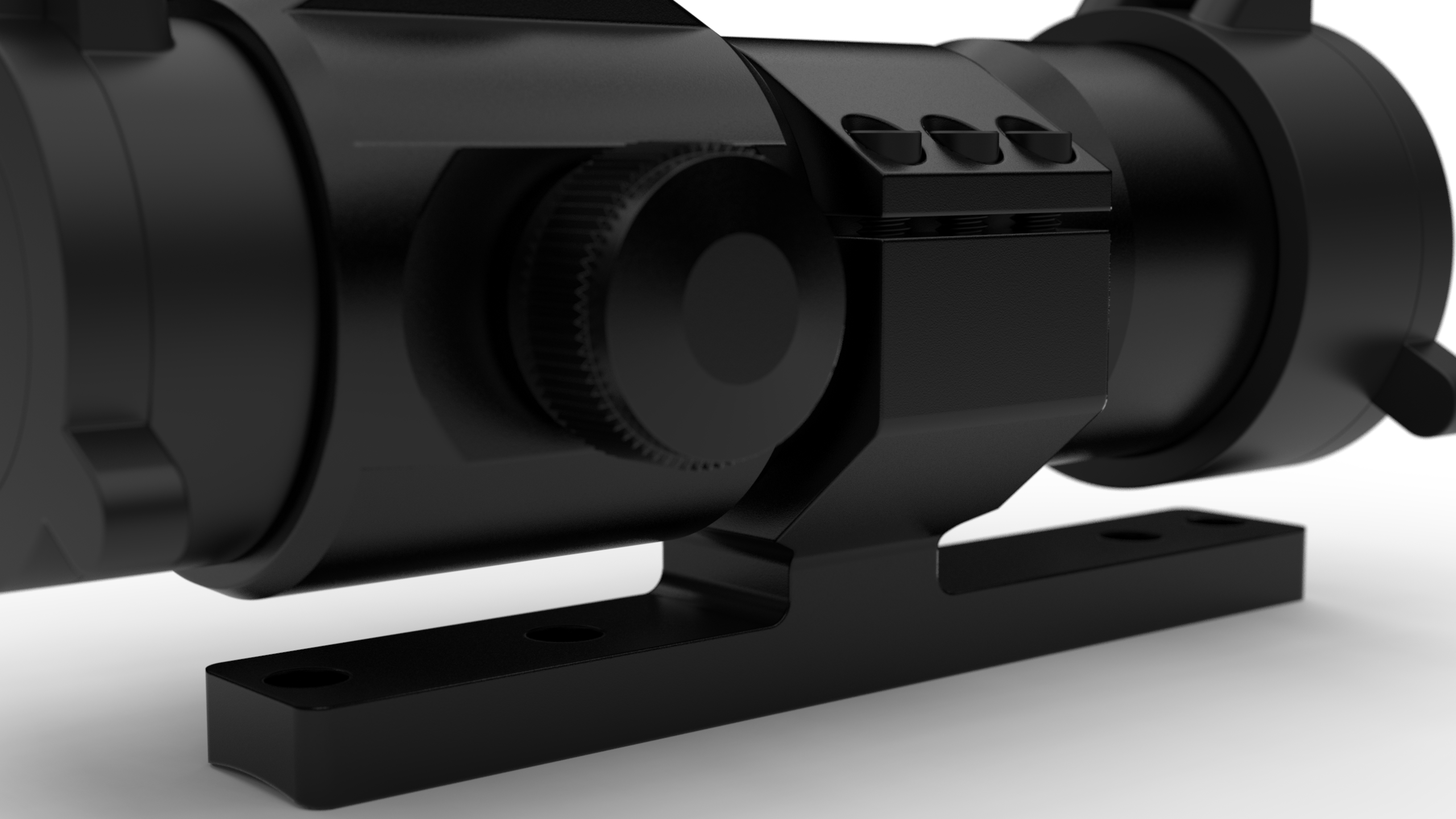

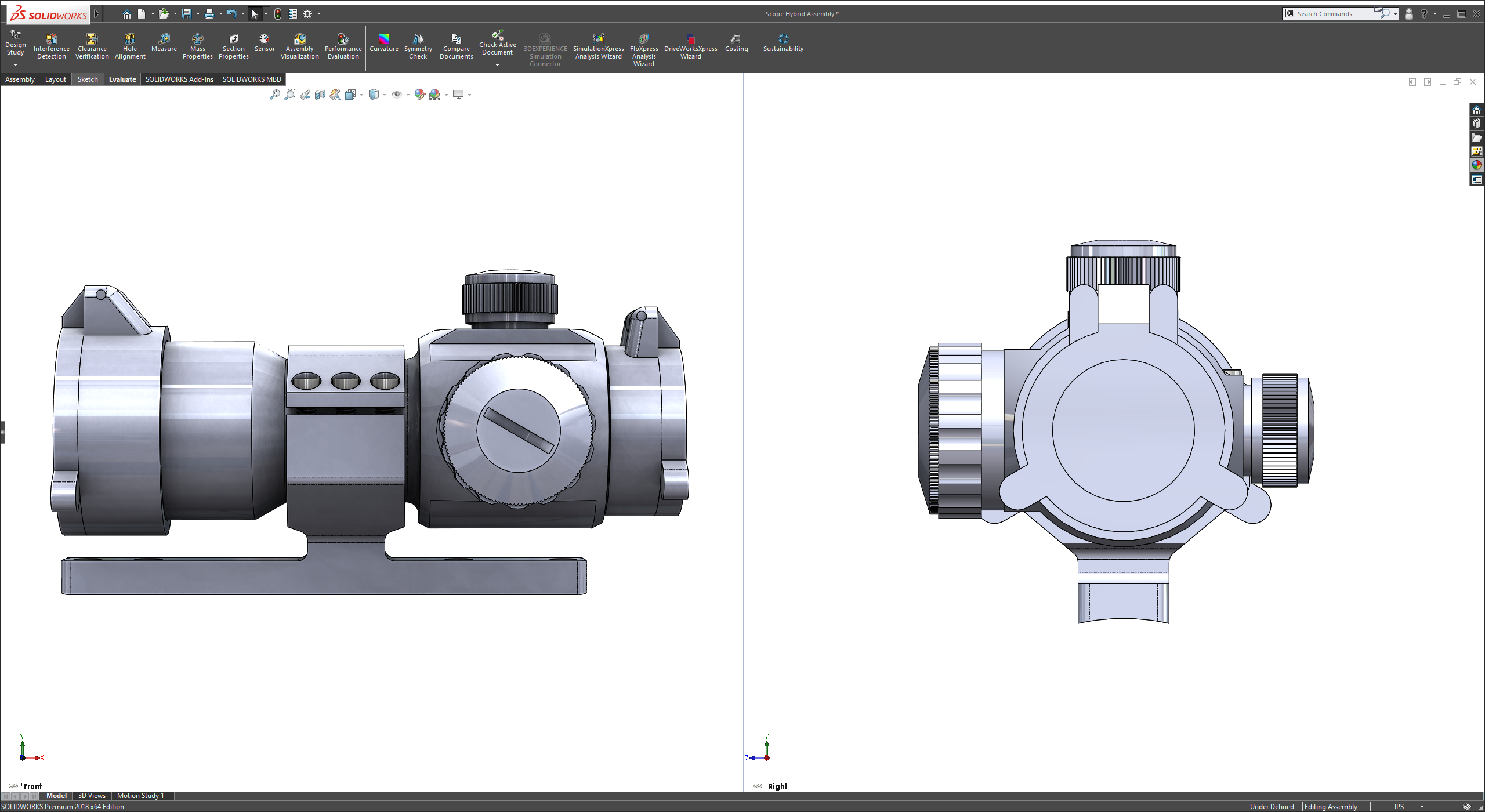

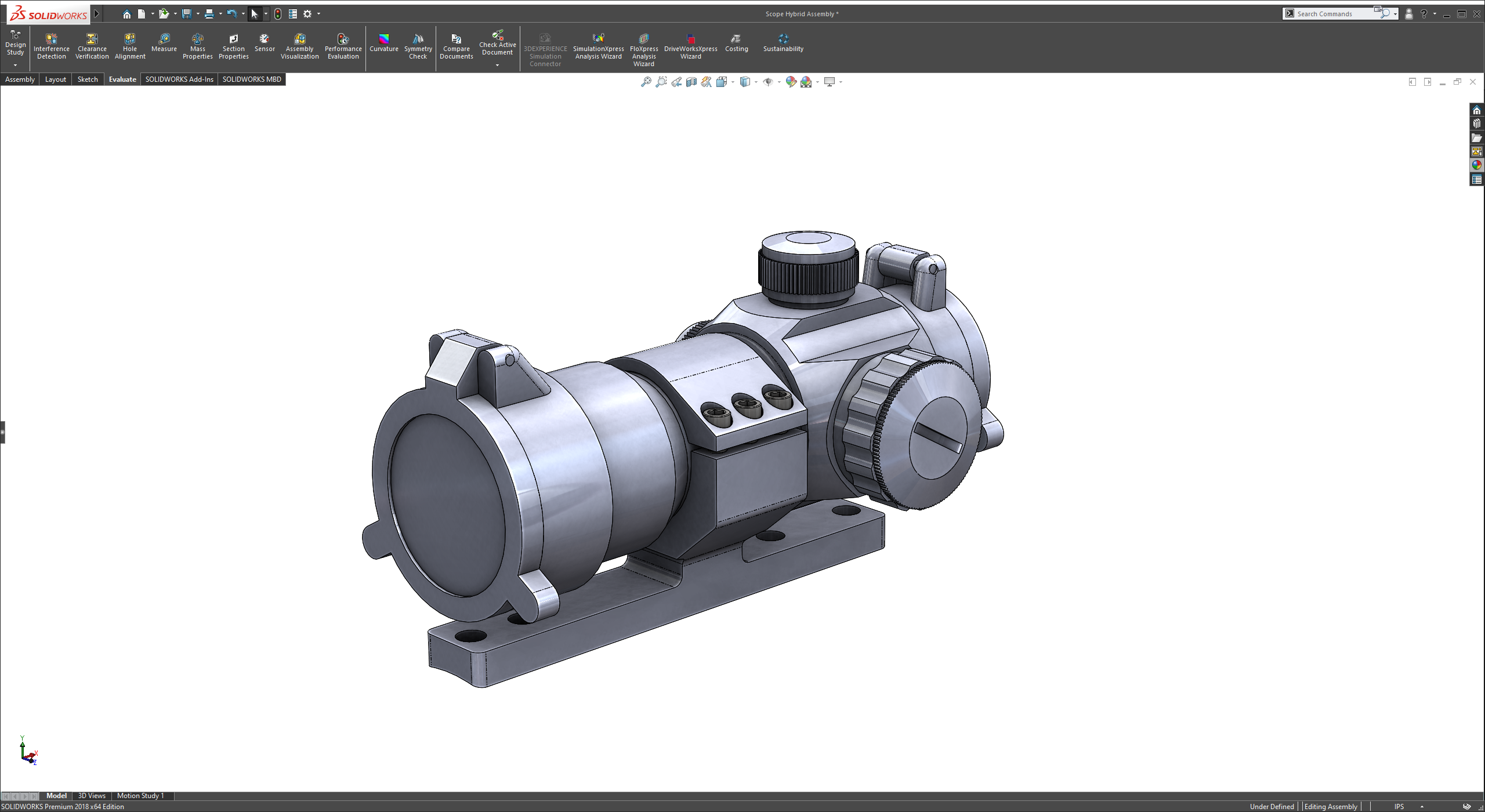

After the part was measured, we constructed the 3D CAD model of the hybrid scope in SolidWorks. To make sure the designed of the hybrid mount looked right we also modeled in the G4 Scope. This would give us an idea of how the final design would look aesthetically as we made tweaks.

During this development process we made sure to to keep the rules of designing this for CNC manufacturing while being cost effective and along the way checking for tolerances and clearances between mating components.

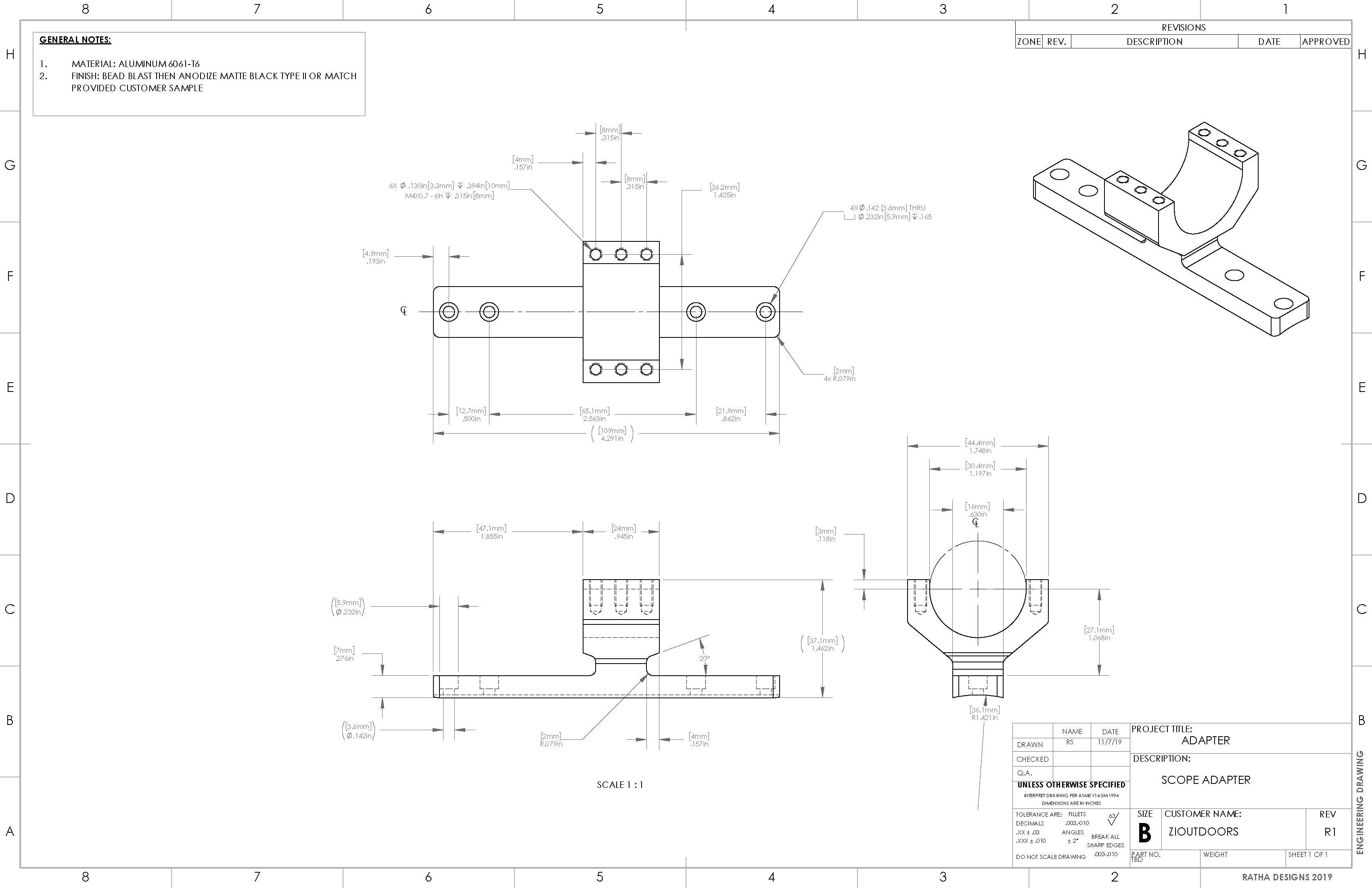

2D Drawing

Once the design met both Greg’s and I satisfactory, a STEP file and 2D drawing was created and exported. These files would be the essential requirements for Greg to get a accurate quote from machining manufactures domestically and overseas. Because Greg had access to me he also had access to my network when finding a trusted and reliable manufacturing contact.

Production

First samples have been made and Greg is looking to put in order for a production quantity and will be available soon to purchase on Amazon.

[TEST_B id=4287]

Ready to get started?

Credits